Vapour Recovery Unit Off-skid Engineering Detailed Design

PROJECT SUMMARY

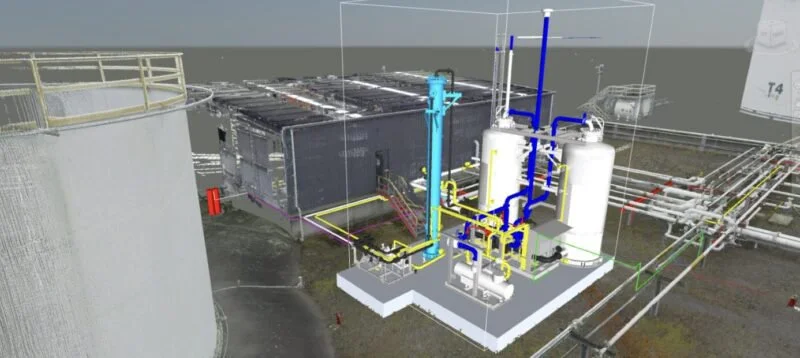

Installation of a $2.5 million dollar Vapour Recovery Unit (VRU) at the clients Storage and Road Loading Terminal. The VRU will condense petrol vapour currently vented to atmosphere during road tanker loading and return it as captured product to their storage tanks. The VRU is expected to recover 400,000 litres of petrol vapour annually, reducing carbon emissions by around 1 million kilograms each year.

SCOPE

The Five-D scope for the VRU project is engineering detailed design for all off-skid piping and the foundation for the VRU Unit. This involved:

Process Engineering to complete P&IDs, Off-Skid Equipment Sizing and Process Data.

Vapour Recovery piping from the Gantry Building to the VRU Skid.

Absorbent Inlet Piping from Tanks 2 & 3 to the VRU Skid (via pump P-301 located in the Gantry Building).

Absorbent Outlet Piping from the VRU Skid to Tank 2&3.

Instrument Air and N2 Hookup to the VRU skid.

VRU structural foundation design, stairs, handrails, and associated pipe supports.

Procurement Support for any valves/instruments associated with the above Off -skid piping.

Project management to support the above activities.

The project utilised a 3D scan of the facility with all mechanical and structural design completed in the 3D model space to enable design reviews with the client, VRU provider and the design team to enable clash detection and ensure all operability/maintainability requirements are achieved.

The integrated project team included Process Group (PGL) for the project process design and CSEng for the VRU structural foundation design, stairs, handrails, and associated pipe supports.

CHALLENGES

Review of preliminary design identified significant challenges to enable the location of the inlet absorbent pump withing the road loading gantry building situated 180m from the storage tanks. The Five-D proposed solution to change the piping tie-in locations not only enabled the pump to be installed in the client preferred location it reduced the amount of new piping (and associated pipe supports) by over 150m and provided the client with the flexibility to connect VRU absorbent to more than one storage tank.

OUTCOME

The project is currently working through the design phases and is expected to be completed and commissioned in the third quarter of 2024